Deutz series TCD 2012 – это 4-х тактные 4-х и 6-ти цилиндровые дизельные двигатели для мобильной техники средней мощности с верхним расположением клапанов (OHV), горизонтальным валом отбора мощности, с жидкостным охлаждением ориентированные на эксплуатацию в нормальных климатических условиях. Выпускаются мощностью от 88.5 л.с. (66 кВт) до 208 л.с. (155 кВт), с турбонаддувом, с механическим или электронным инжектором.

Приемуществами Deutz серии TCD2012 являются: низкий уровень шума; компактность конструкции при относительно большой мощности двигателя; повышенная надежность и долговечность, благодоря применению современных технологий производства и качеству материалов. Соответствуют нормам по газовым выбросам ЕС Step III A и Tier 3 (США).

Вы можете приобрести как комплектные двигатели Deutz, так и комплектующие, расходники и запасные части на необходимую Вам силовую технику Deutz.

Моторы Deutz TCD2012 серии широко используются в составе различной строительной техники: колёсных и гусеничных экскаваторов, погрузчиков, буровых установок, комбайнов, компрессоров, дизельгенераторов и др.

Related Posts:

Table of error flash codes

Possible light codes, their meaning, as well as ways to eliminate errors are listed in the table on the next page. The data of the light codes in the first column indicate the number of short light signals issued (the burning time is about 0.4 s), the number of subsequent long light signals (the burning time is about 0.8 s), and the number of trailing short light signals. Error code 2-1-4 “Exceeding speed” consists, for example, of two short, one long and four short light signals. If you can not solve the error using the methods listed in the table, contact your local authorized DEUTZ partner.

| Title | File Size | Download Link |

| DEUTZ EMR3 – Diagnostic trouble codes DTC.pdf | 289.4kb | Download |

| Deutz TCD 2015 V08 EMR3 Diagnostic trouble codes.pdf | 62.4kb | Download |

| DEUTZ Trouble Code List EMR4.pdf | 996.4kb | Download |

| Dtc List Deutz Engine.pdf | 359.9kb | Download |

| EMS2 Deutz Fault Codes.pdf | 1.3Mb | Download |

| Tabela de Falhas Motor Deutz.pdf | 556.3kb | Download |

Deutz Flash Codes

| Short (0.4 C) |

Long (0.8 c) |

Short (0.4 C) |

Function / Component | Error |

|---|---|---|---|---|

| 1 | 2 | 3 | Output к Lamps Temperature Cooling Liquid | Wrong signal, exceeding device temperature Management |

| 1 | 2 | 6 | Adjustment Number Revolutions Manually | Wrong / Incomprehensible Signal |

| 1 | 2 | 8 | Sensor Temperature Intake Air | Wrong Signal |

| 1 | 3 | 3 | Sensor Temperature Transmission Oil | Wrong Signal |

| 1 | 3 | 4 | Control Pressure System Rail | Incomprehensible signal, pressure/deflection of pressure Limits of permissible range |

| 1 | 3 | 5 | Output to the oil pressure signal lamp | Wrong signal, exceeding device temperature Management |

| 1 | 3 | 5 | Output To the valve of the dosing unit Fuel | Wrong signal, exceeding device temperature Management |

| 1 | 3 | 6 | Control Air Filter | The air pressure behind the filter is too low |

| 1 | 3 | 7 | Output To Executive Devices | Short Circuit On Battery |

| 1 | 3 | 8 | Output To Executive Devices | Short Circuit On Housing |

| 1 | 4 | 2 | Output to the engine work lamp | Wrong signal, exceeding device temperature Management |

| 1 | 4 | 3 | Multi Switch 1 / 2 / 3 | Wrong / Incomprehensible Signal |

| 1 | 4 | 4 | Sensor Temperature Lube Oil | Wrong / Incomprehensible Signal |

| 1 | 4 | 4 | Control Temperature Oil | Temperature Out Specified Range |

| 1 | 4 | 5 | Control Switch Lock Automation | Incomprehensible Signal |

| 1 | 4 | 6 | Reducing Valve System Rail | Valve Opened / Need Push Pressure / After Push Pressure Not Open |

| 1 | 4 | 7 | Sensor Pressure System Rail | Incorrect signal, deviation of pressure outside Valid range |

| 2 | 3 | 1 | Control Pressure Oil | Pressure Out Specified Range |

| 2 | 3 | 2 | Control Temperature Cooling Liquid | Temperature Above Specified Range |

| 2 | 3 | 3 | Control Temperature Intake Air | Temperature Above Specified Range |

| 2 | 3 | 5 | Control Level Cooling Liquid | Level Below Specified Range |

| 2 | 3 | 7 | Control Temperature Fuel | Temperature Out Specified Range |

| 2 | 3 | 8 | Output To Executive Device Fan 1/2 | Wrong signal, exceeding device temperature Management |

| 2 | 3 | 8 | Control Number Revolutions Fan | Number of revolutions outside the specified range |

| 2 | 4 | 1 | Control Combustion | Ignition interruptions detected in one or more Cylinders |

| 2 | 6 | 1 | Exit control To Executive Devices | Relay Not Open Or Open с Late Short Closure on Housing |

| 2 | 6 | 3 | Output To A device that facilitates Cold start | Incorrect signal, malfunction of the relay, seizes or Incorrectly connected, short circuit |

| 2 | 7 | 1 | Bus CAN | One or more data block timeouts, Bus inactive |

| 2 | 8 | 2 | Voltage Power Sensor 1 / 2 / 3 | Voltage outside the specified range |

| 2 | 9 | 2 | Sensor Atmospheric Pressure | Wrong / Incomprehensible Signal |

| 3 | 1 | 4 | Temperature sensor Oil For Hydraulic system | Wrong Signal |

| 3 | 1 | 4 | Temperature control Oil For Hydraulic system | Temperature Out Specified Range |

| 3 | 1 | 8 | Control Battery | Voltage Out Specified Range |

| 3 | 2 | 8 | Output to the control lamp of the device, Facilitating cold start | Wrong signal, exceeding device temperature Management |

| 4 | 1 | 4 | Exit to the external executive Device AGR | Wrong Signal |

| 4 | 1 | 5 | Exit to the external executive Device AGR | Wrong signal, exceeding device temperature Management |

| 4 | 1 | 6 | Exit to the external executive Device AGR | Wrong Signal |

| 4 | 1 | 7 | Chronometer Export Lube Oil | Reached Critical Just a moment |

| 5 | 1 | 2 | Output To Gauges Relay | Wrong signal, exceeding device temperature Management |

| 5 | 1 | 3 | Exit to the bulb-error indicator | Wrong signal, exceeding device temperature Management |

| 5 | 1 | 4 | Control Terminal 15 | Not Detected Signal |

| 5 | 1 | 5 | Control Terminal 50 | Detected Permanent Signal |

| 5 | 2 | 1 | Measurement Speed | Speed Movement Incomprehensible |

| 5 | 2 | 8 | Exit to internal motor brake | Wrong Signal |

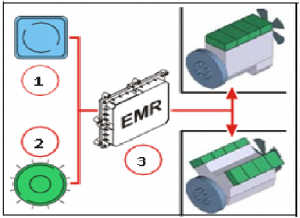

Engine protection by EMR3 system

When all errors are eliminated, the error indicator lamp goes out. At some errors it is necessary to switch off ignition, to wait 30 with and only then again to include ignition.

Depending on the construction of the monitoring function, the EMR3 can protect the engine from damage in some emergency situations, monitoring compliance with important limit values during operation and verifying the proper functioning of the system components.

When the sensor fails, the corresponding monitoring functions are disabled. Only the sensor output is faulty in the fault memory.

Depending on the degree of severity of the detected error, the engine can continue to operate with restrictions (the error indicator light is continuously on), or the error indicator lamp flashes, indicating a serious system error. In this case, the engine should be switched off as soon as it is safe. Depending on the configuration of the engine, the flashing of the error indicator light may indicate the following:

- The requirement to switch off for the person carrying out the operation. Attention: if non-observance is lost, the warranty is lost!

- Automatic engine shutdown after a short warning time, possibly related to start-up.

- Forced engine operation at low idle speed for engine cooling, if necessary with automatic shutdown.

- Prohibition of starting.

Using the Diagnostic Button

The diagnostic button (1) makes it possible to read the existing errors in the form of light codes. The diagnostic button (1) and the error indicator light (2) are located on the control panel of the vehicle.

The occurrence of errors indicates the flashing or continuous burning of the error indicator light (2). To get more precise information about all the errors that exist, they can be read in the form of light codes as follows (only when the engine is off): After pressing the diagnostic button (1) for at least one second, the error indicator (2) goes out and the first error is issued as a light code after releasing the button. Light codes should be decoded according to the table on the next page. After issuing the error light code, the error indicator lamp (2) goes out for five seconds.

Then, by repeatedly pressing the diagnostic button (1), the following error (i.e., the next in the error memory) can be displayed. If the last error is displayed, the next time you press the diagnostic button (1), the first error will be displayed again.

DEUTZ EMR3 – Diagnostic trouble codes DTC PDF – download

Современные двигатели Deutz TCD 2012 были разработаны для спецтехники средней мощности. В моторах реализованы такие инновационные решения, как система прямого впрыска топлива под высоким давлением CR, разработанная инженерами компании Deutz, электронная система управления силовым агрегатом с возможностью адаптации используемых настроек. Двигатели комплектуются турбонаддувом с системой охлаждения воздуха, системой водяного охлаждения. Объем каждого цилиндра 1,01 л, их верхнее расположение упрощает обслуживание, что позволяет увеличить срок службы двигателя.

Производители сельскохозяйственной, садовой, дорожной и строительной техники используют двигатели Дойц TCD 2012 для комплектации высокопроизводительных моделей. В числе основных преимуществ моторов серии:

- небольшие габариты и простой монтаж;

- широкий диапазон применения;

- отличные рабочие характеристики при небольшом расходе топлива;

- простой и плавный запуск при отрицательной температуре;

- продолжительные межсервисные интервалы снижают текущие расходы на обслуживание техники;

- полная адаптация к использованию топлива с высоким содержанием серы.

Все моторы серии отвечают требованиям экологического стандарта Tier III, отличаются низким уровнем шума в работе.